The adaptability of a centrifugal brakes can be attributed to the many configurations and applications for which it is suited. From microcentrifuges that are used in genetic testing to heavy-duty machines for industrial processing, each is optimized for a particular purpose. The latest versions usually come with wireless monitoring systems, whose real-time data tracking occurs through mobile interfaces. Improved rotor materials allow for higher strength and corrosion resistance. In addition, automated calibration systems reduce maintenance time while improving consistency in performance. With these advancements, the centrifugal brakes is a vital instrument in the continued search for scientific precision and efficiency.

The versatility of centrifugal brakes can be seen in its application to numerous specialized fields. In marine biology, it helps one analyze plankton and microbial samples. In food science, it helps with the accurate measurement of fat and protein content. The electronics sector employs centrifugal brakes for purifying liquid crystals and conductive materials. In environmental protection, centrifugal brakes facilitate tracking of pollutants and studies on recycling. They aid in veterinary medicine in blood diagnosis and disease investigation. With these uses, centrifugal brakes bring about innovation through offering dependable means for analyzing as well as separating materials.

The centrifugal brakes technology future lies in automation, digital control, and green engineering integration. Future models will include AI algorithms for speed, balance, and separation efficiency automatic optimization. Energy-efficient motors and recycled materials will reduce environmental impact, following international sustainability goals. Cloud connectivity will allow for remote monitoring and predictive maintenance, with less downtime. In laboratories, centrifugal brakes will be completely compatible with smart data systems for real-time reporting and process validation. These innovations promise greater accuracy, reliability, and versatility for research and industrial use.

Accurate maintenance ensures that centrifugal brakes functions properly and safely in the long term. Regular cleaning after use prevents creation of residues that affect rotation balance. Users should inspect rotors from time to time for signs of wear and have them replaced once such signs are noticed. Calibration and balancing checks should be on a predetermined schedule. All seals and gaskets should remain in place to prevent leakage during use. Storage of equipment is to be in a stable, dry location. Proper maintenance not only preserves function but also safeguards the accuracy of every experimental result.

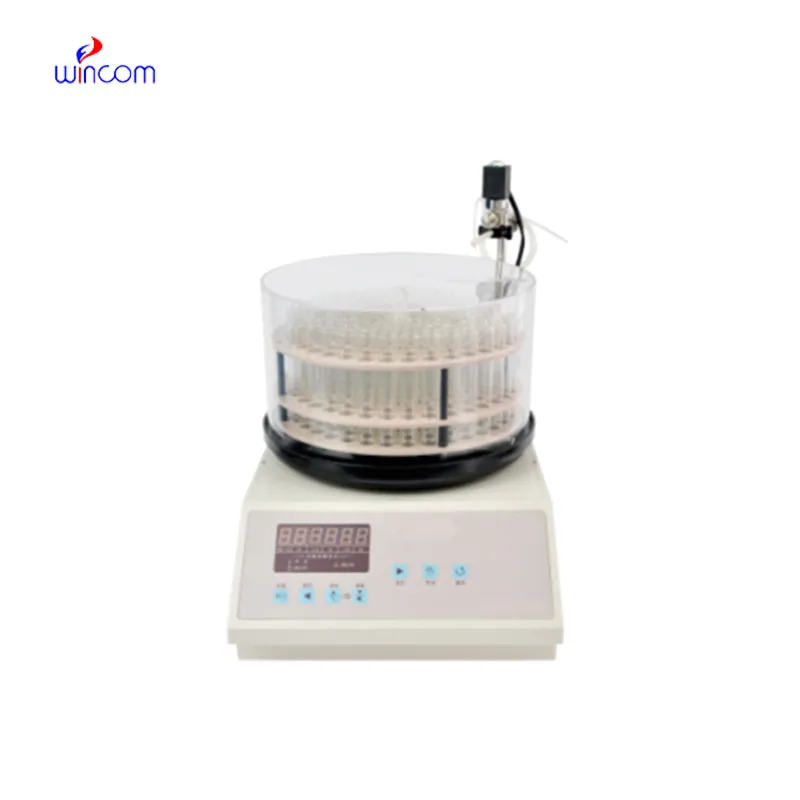

The centrifugal brakes is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. centrifugal brakes also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and centrifugal brakes are thus inevitable in numerous modern applications.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

Could you please provide more information about your microscope range? I’d like to know the magnif...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China