Recent innovations in centrifugally technology focus on the improvement of automation as well as information integration. Intelligent models now communicate with laboratory information management systems so that the recording of experimental parameters is no longer problematic. Noise reduction modules and ergonomic covers have also increased user comfort and safety. Also, controlled temperature chambers and high-speed rotors facilitate the handling of sensitive material without degradation. Such technology renders centrifugally equipment more adaptable to varying research needs, offering unparalled precision in particle separation and purification processes in countless industries.

From research in the laboratory to large-scale production, centrifugally devices have a place in processes requiring precision and efficiency. They purify reaction mixtures and solvents in chemical production. Hospitals rely on centrifugally for the testing of patients and therapeutic treatment. In farming, centrifugally are used to study plant biology and develop fertilizer formulations. In brewing and winery operations, they provide consistency within products by filtering out impurities. Even environmental engineers rely on centrifugally to filter sediment as well as identify contaminants. Such wide-ranging functionality demonstrates its vital position in contemporary technology and applied sciences.

centrifugally will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up centrifugally for specific scientific or industrial uses. These improvements will allow centrifugally to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

For long-term efficiency, centrifugally must be maintained with thorough attention to detail of operation. Every rotor and adapter must be checked for integrity before sample loading. After every cycle, the apparatus needs to be washed with neutral detergents and dried thoroughly. Vibration and mechanical stress are prevented by regular tests of balance. Seals and filters need to be replaced according to service schedules. Dust deposition is prevented by keeping the instrument in a covering when not used. If centrifugally apparatus is cared for according to disciplined procedure, equipment will give consistent high-performance performance year in year out.

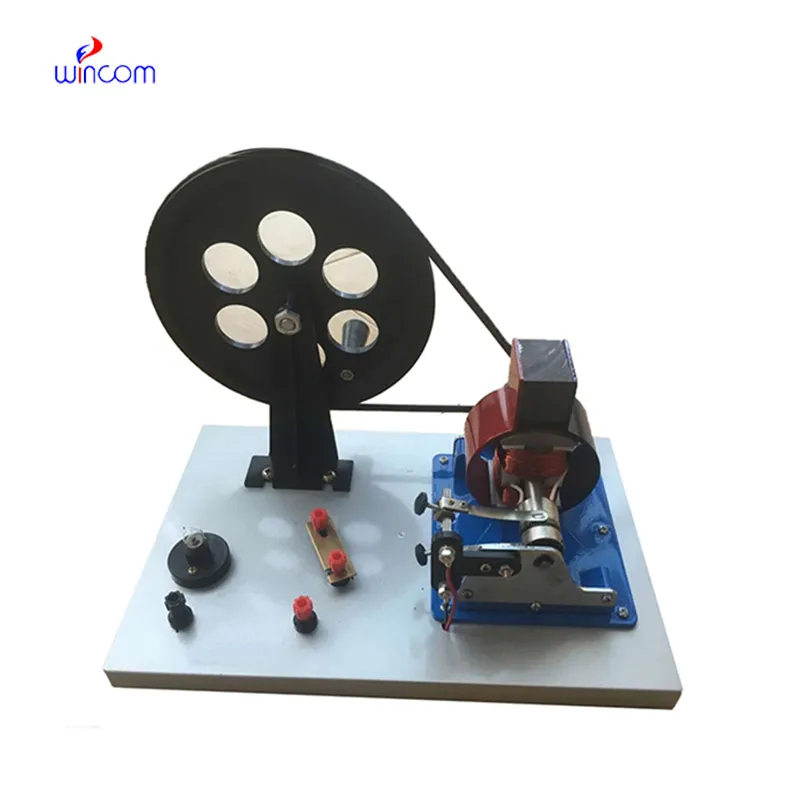

A centrifugally makes the principle of rotational motion a tool of scientific inquiry and industrial productivity. Unrelenting spinning power applied to it fractions different materials in a sample on the basis of weight. It makes necessary procedures such as the analysis of blood, protein separation, and sewage treatment possible. centrifugally today combine strength with precision by offering variable speed ranges and advanced control mechanisms. Their use also extends beyond laboratories to fields like aerospace and environmental monitoring, showing both their scientific and utilitarian applications.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China