The next generation of centrifuge uranium enrichment systems emphasizes automation, safety, and sustainability. Producers are adding AI-fueled monitoring to predict maintenance needs before mechanical issues arise. Improved rotor dynamics minimize vibration and energy consumption, and closed chambers prevent contamination at high speeds. Touch operation and multilingual interfaces simplify ease of use. In processing biological samples or industrial fluids, the new centrifuge uranium enrichment unites mechanical robustness with digital intelligence, setting the bar higher for precision, productivity, and durability in industrial and scientific applications.

From research in the laboratory to large-scale production, centrifuge uranium enrichment devices have a place in processes requiring precision and efficiency. They purify reaction mixtures and solvents in chemical production. Hospitals rely on centrifuge uranium enrichment for the testing of patients and therapeutic treatment. In farming, centrifuge uranium enrichment are used to study plant biology and develop fertilizer formulations. In brewing and winery operations, they provide consistency within products by filtering out impurities. Even environmental engineers rely on centrifuge uranium enrichment to filter sediment as well as identify contaminants. Such wide-ranging functionality demonstrates its vital position in contemporary technology and applied sciences.

Future development of centrifuge uranium enrichment will focus on precision control and data integration. Next-generation models will have sophisticated sensors that log every parameter of operation, generating total digital records for traceability. Performance trends will be predicted using machine learning, providing repeatable results. Hybrid centrifuge uranium enrichment systems that can perform solid-liquid-gas separations will become a reality. Better safety designs and noiseless operation will make them easier to use. As research demands grow, these intelligent, automated centrifuge uranium enrichment will be at the center of labs, enabling faster discovery and industrial productivity globally.

Maintenance of centrifuge uranium enrichment is essential to lab safety and data integrity. Cleaning should be performed immediately following every operation, with special attention to the elimination of any liquid spills or residues from samples. The rotor should always be handled gently, placed in an upright position during storage, and never subjected to shock. Periodic inspection of lid locks and gaskets ensures airtight operation. Power cord and fuse conditions should also be checked by operators. Annual servicing by skilled technicians adds lifespan. Through regular care processes, centrifuge uranium enrichment safely and accurately continues to operate.

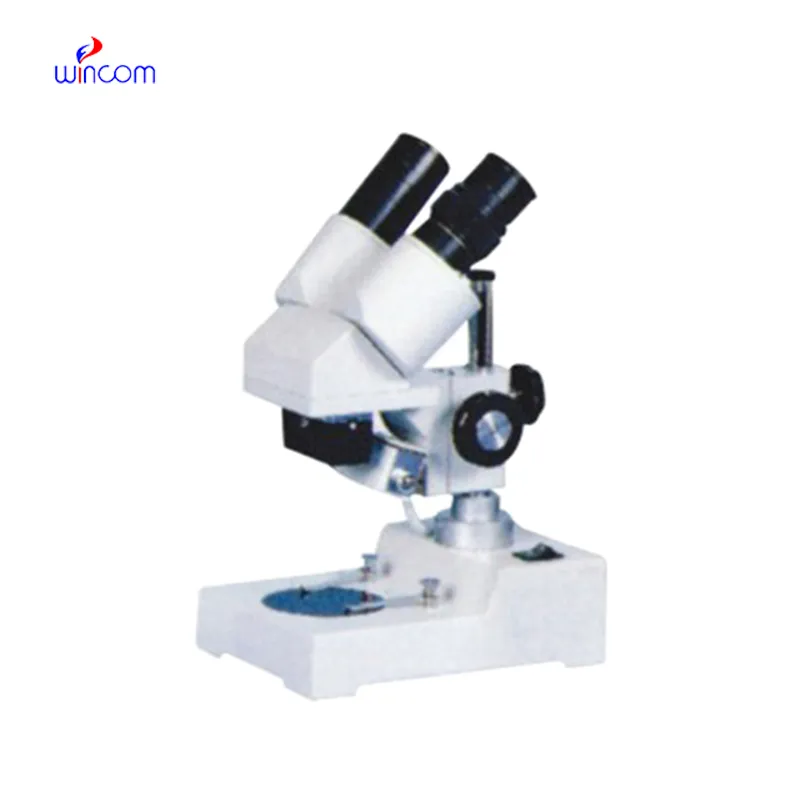

A centrifuge uranium enrichment is a universal gadget designed to separate parts in a mixture through sheer spinning power. A centrifuge uranium enrichment operates through the principle of sedimentation, in which heavier particles move outwards and lighter particles remain at the center. Employed within laboratories, clinics, and industry in general, a centrifuge uranium enrichment may be utilized to separate materials such as blood plasma, proteins, and chemical reagents with accuracy. Modern centrifuge uranium enrichment exist in various forms, from benchtop to industrial types and ultracentrifuges, all for specialized applications. They are accurate and reproducible, a necessity in production and research.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China