In modern-day lab environments, the cold press juicer vs centrifugal is not just a separation apparatus—it is precision engineering. With simple-to-view digital displays and microprocessor controls, it makes it easy for scientists to quickly adjust variables like acceleration and deceleration rates. Other models come equipped with onboard diagnostics that analyze rotor condition and operating performance. High-end safety features like automatic lid interlocks and imbalance detection offer protection at every cycle. With more rapid and consistent processing needed in industries, cold press juicer vs centrifugal technology keeps up with stability, precision, and greater throughput capability.

The use of cold press juicer vs centrifugal traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ cold press juicer vs centrifugal in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize cold press juicer vs centrifugal to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

Sustainability, connectivity, and accuracy will be the areas of future evolution of cold press juicer vs centrifugal. Instruments will be made with sustainable materials and energy-efficient drives to minimize their carbon footprint. Real-time monitoring of data through cloud-based systems will facilitate real-time troubleshooting and process optimization. Portable versions will enhance accessibility in remote- or field-based studies. In pharma and biotech, cold press juicer vs centrifugal will ramp up production with intelligent automation. As technology continues to evolve, cold press juicer vs centrifugal will remain at the center of scientific innovation, bridging the gap between mechanical performance and digital intelligence.

Continuous cleaning and routine checkup maintain a cold press juicer vs centrifugal in good working order. The rotor must be carefully inspected for distortion or corrosion because even small flaws can result in unbalance. Users should clean the interior chamber with a soft cloth at the end of each run to remove residues. Electrical and mechanical components must undergo regular checks for proper alignment and accuracy of speed. Periodic calibration at specified intervals maintains measurement precision. By implementing a formal maintenance regime and strict compliance with manufacturer instructions, the cold press juicer vs centrifugal is dependable upon repetitive application.

A cold press juicer vs centrifugal operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, cold press juicer vs centrifugal facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. cold press juicer vs centrifugal continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

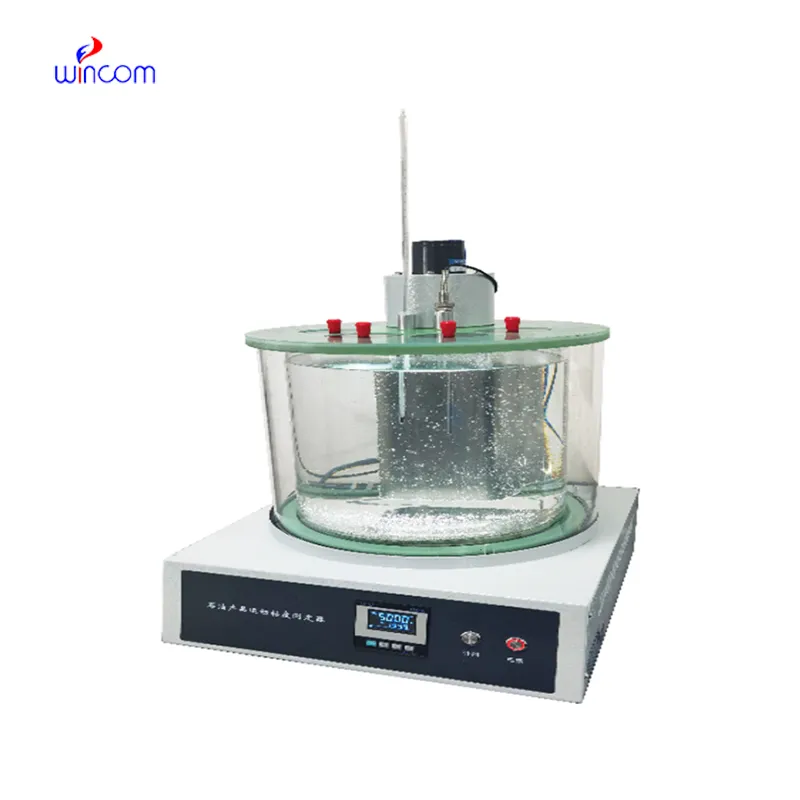

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China