Emerging technologies have driven the performance boundaries of the cold press vs centrifugal juicer, offering improved acceleration rates and greater throughput of samples. Programmable features and touchscreens give users more control over every operation stage. Temperature-controlled cold press vs centrifugal juicer in delicate biological processes guarantee specimen stability over extended cycles. Maintenance-friendly designs and auto-diagnostic programs minimize downtime. The adaptability of next-generation cold press vs centrifugal juicer devices ensures compatibility with any sample type, ranging from microfluidic volumes to industrial suspensions, making it a vital tool in scientific and engineering studies.

The use of cold press vs centrifugal juicer traverses a number of scientific disciplines. In the manufacture of pharmaceuticals, it cleanses chemical compounds and removes residual unwanted matter. Biochemists employ cold press vs centrifugal juicer in fractionating cells and isolating organelles for subsequent studies. Drink producers utilize it to filter fluids and stabilize their products. The oil and gas industries utilize cold press vs centrifugal juicer to enhance fuel refining and clean products. {Keywords} can also be utilized in environmental analysis, aiding in the detection of pollutants in water and air samples. They are highly accurate and flexible, thus being a fundamental tool within laboratories and the manufacturing industry.

In the coming years, cold press vs centrifugal juicer development will move towards intelligent and autonomous operation. Artificial intelligence will predict sample behavior, with speed and duration controlled in real time. Quieter, more compact designs will be the priority for manufacturers to conserve space. Future cooling systems will benefit temperature-sensitive applications, with more widespread use in genomics and proteomics. Wireless connectivity and autocalibration will make it easier to manage cold press vs centrifugal juicer in busy laboratories. With the environment leading the way in manufacturing, recyclable materials and energy efficiency will also define cold press vs centrifugal juicer development in science and industry.

For optimal performance, cold press vs centrifugal juicer equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of cold press vs centrifugal juicer in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

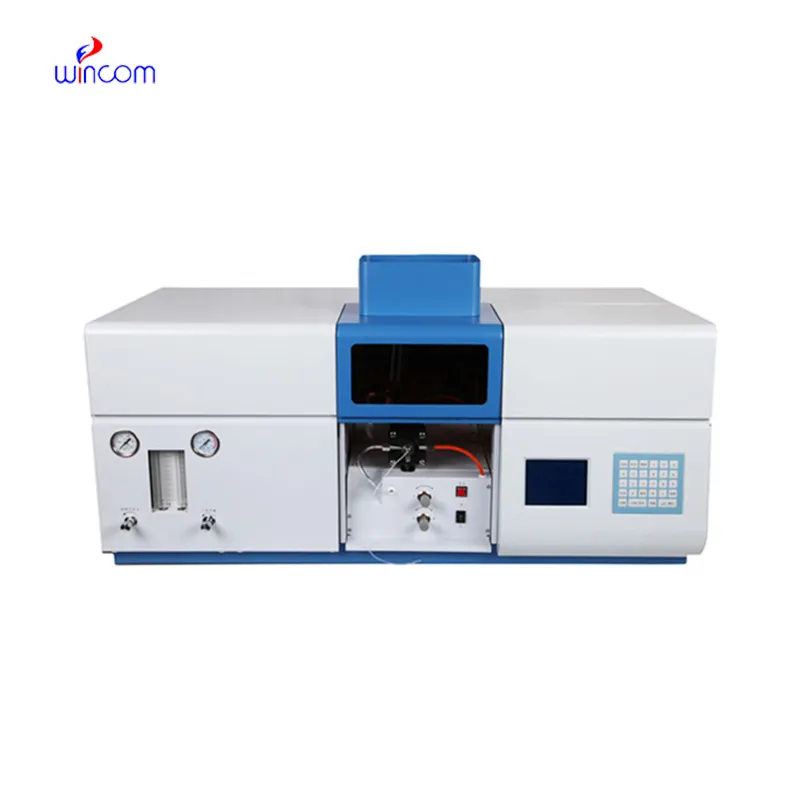

The cold press vs centrifugal juicer is an essential instrument in science and engineering. It is able to separate material constituents based on their differences in density by rotating them at very high speeds. In biotechnology, it is used to purify cells, DNA, and enzymes. In chemistry, it purifies liquids and removes impurities from them. cold press vs centrifugal juicer also play a crucial role in medical diagnosis when preparing blood samples. Their mechanical precision and regulation of speed ensure safe use. Constantly enhanced design and electronic monitoring system development enhances efficiency, and cold press vs centrifugal juicer are thus inevitable in numerous modern applications.

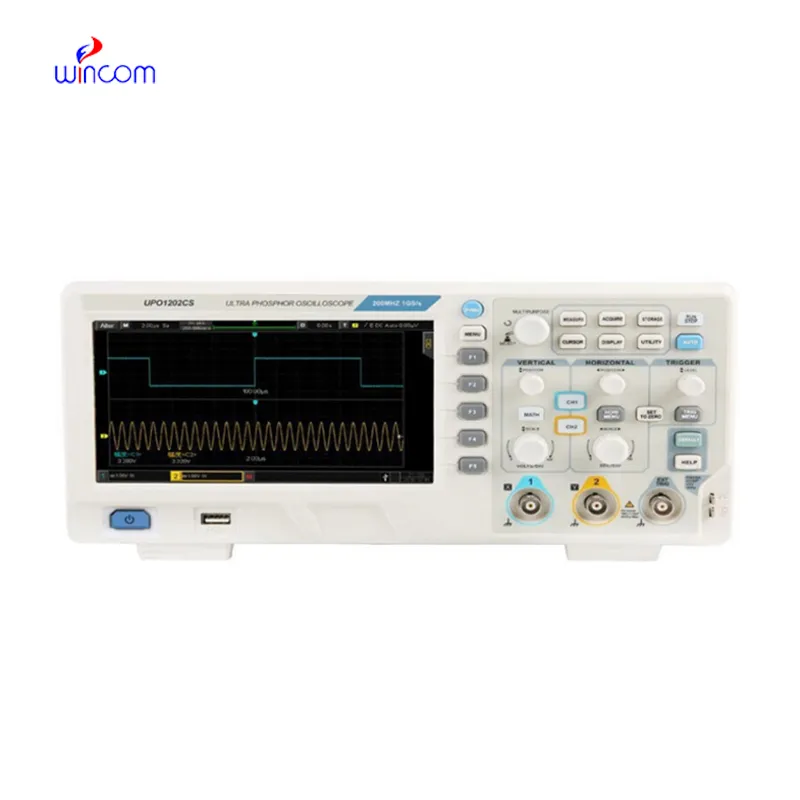

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China